Well, what an amazing week!

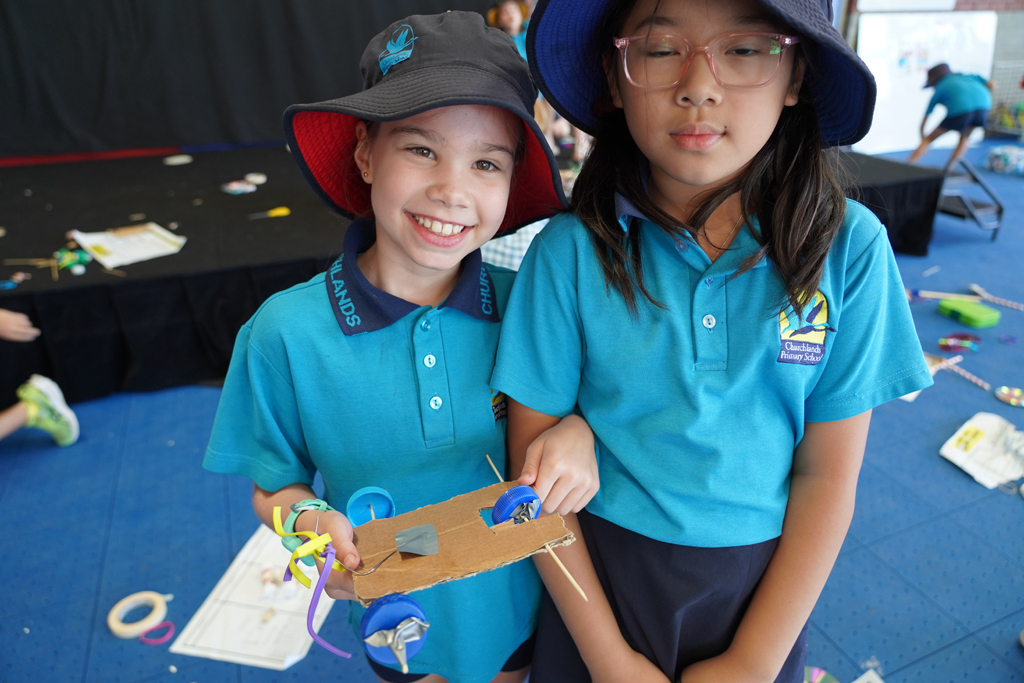

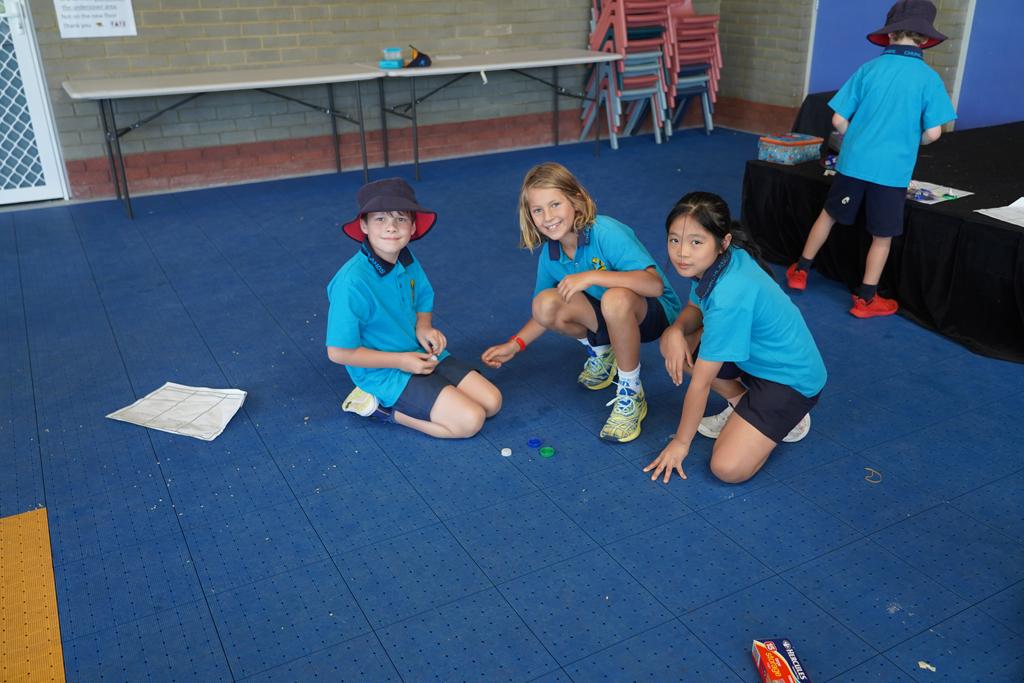

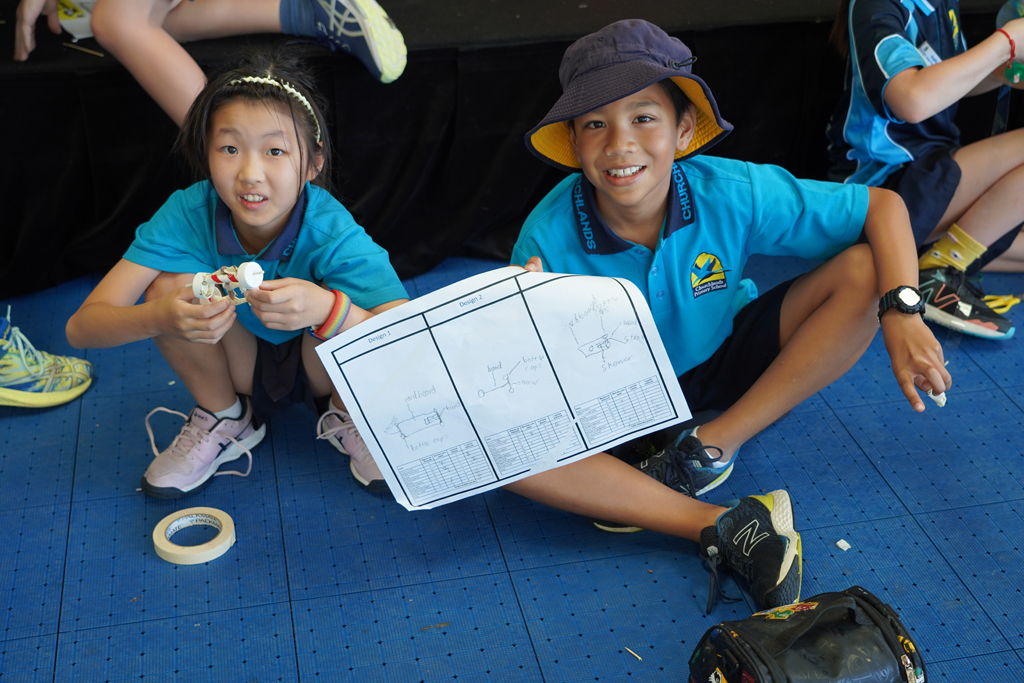

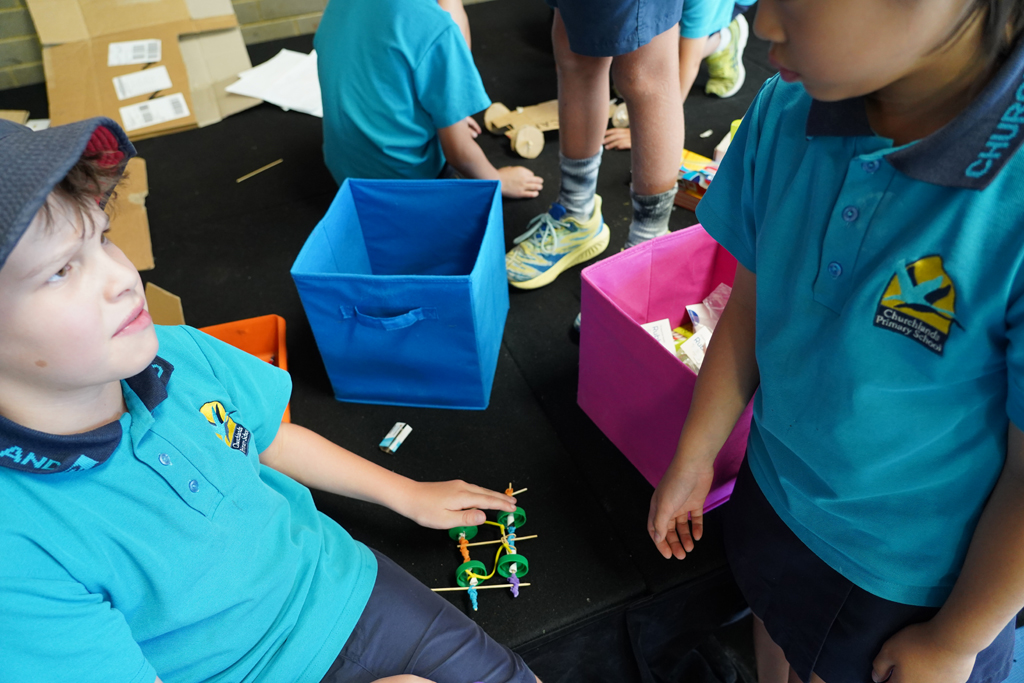

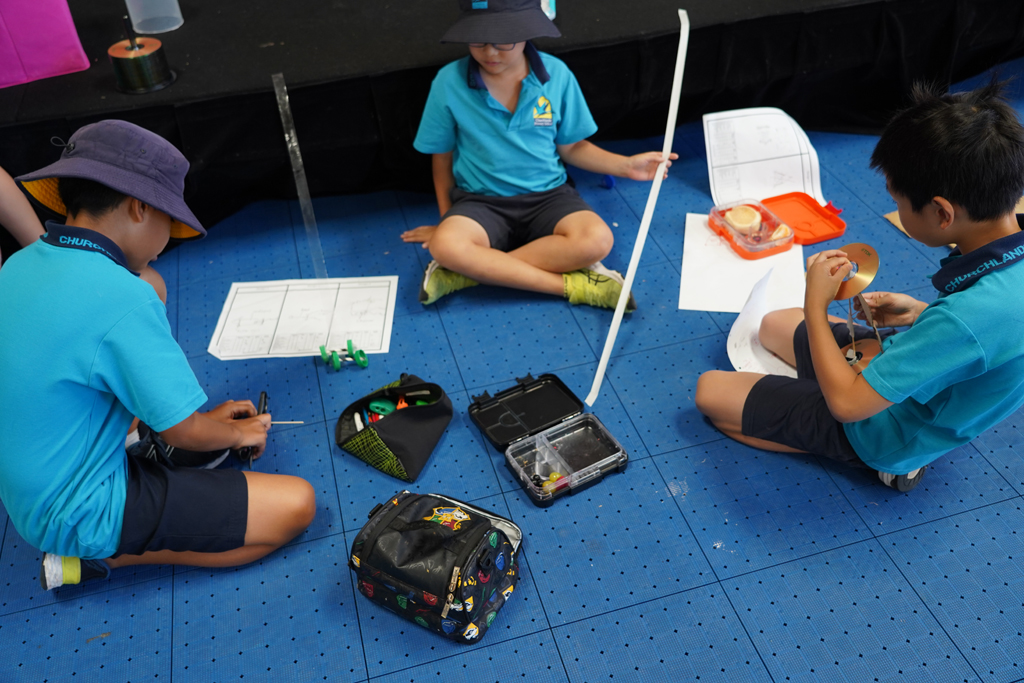

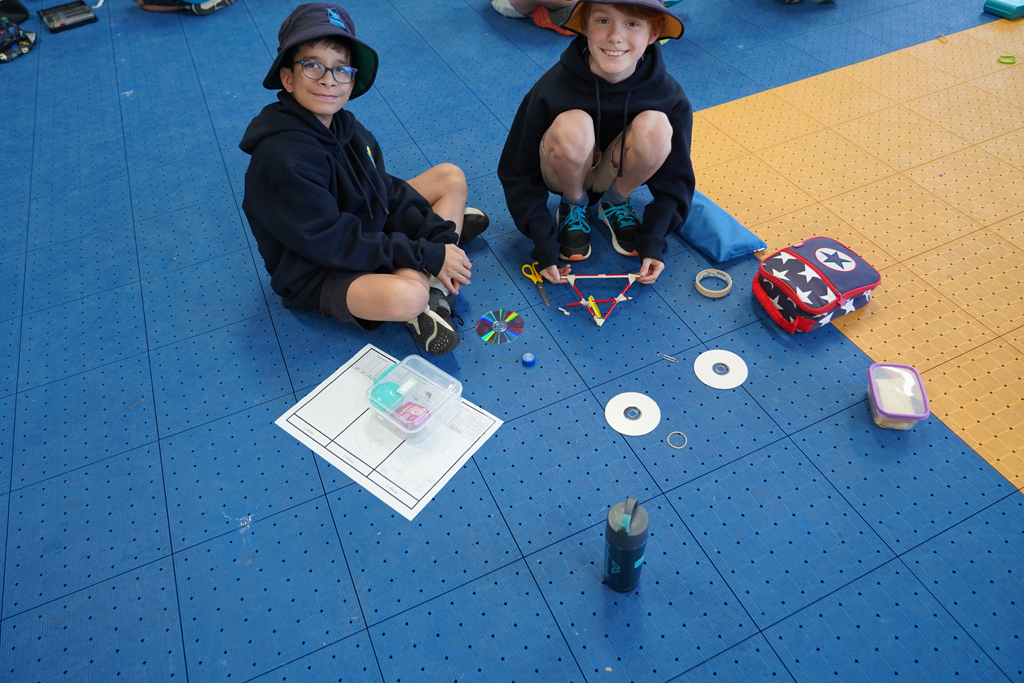

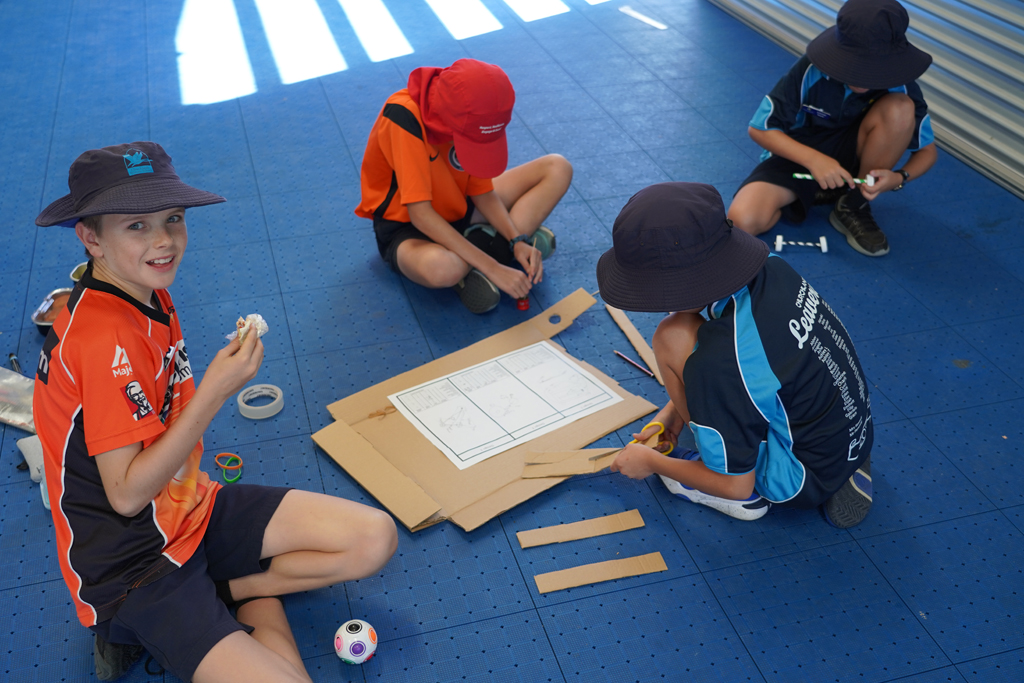

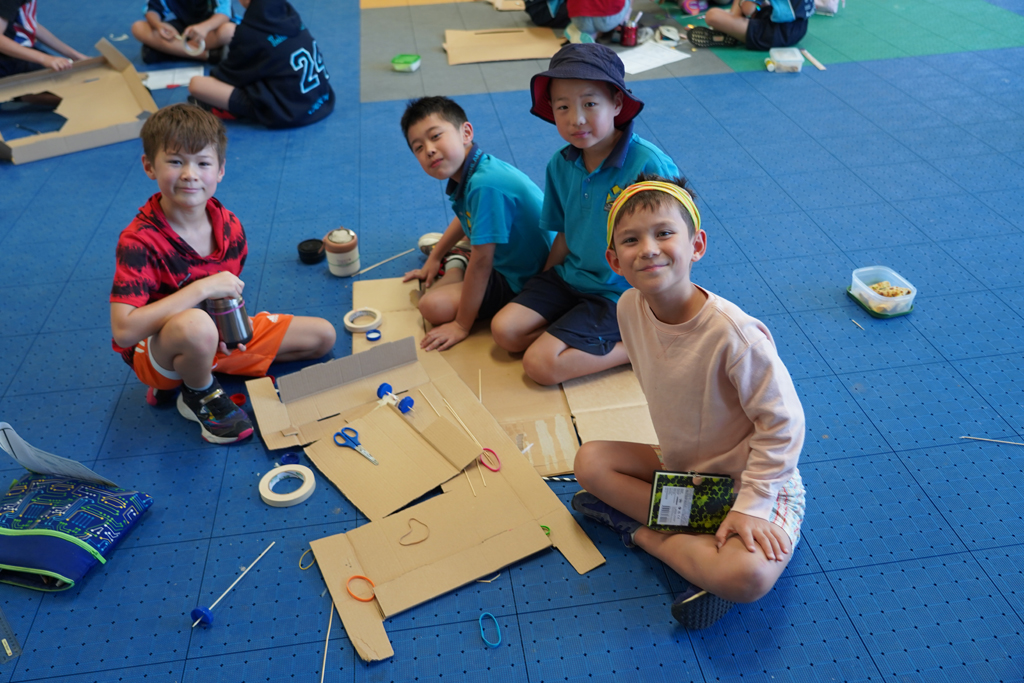

Every lunchtime, and even some recesses, this week we have had over 20 teams of students from years 3 to 5 participating in the Rubber Band Car Engineering challenge. All teams were in the ‘groove’ demonstrating amazing flow as they demonstrated fantastic problem-solving, ingenuity and most importantly, teamwork.

We did find that along the way it was important to demonstrate resilience and persistence as it was a very difficult challenge. It was great to have a conversation with the students about enjoying the journey and to take the positives of the experience, even if the final results or final product did not end up as they had hoped.

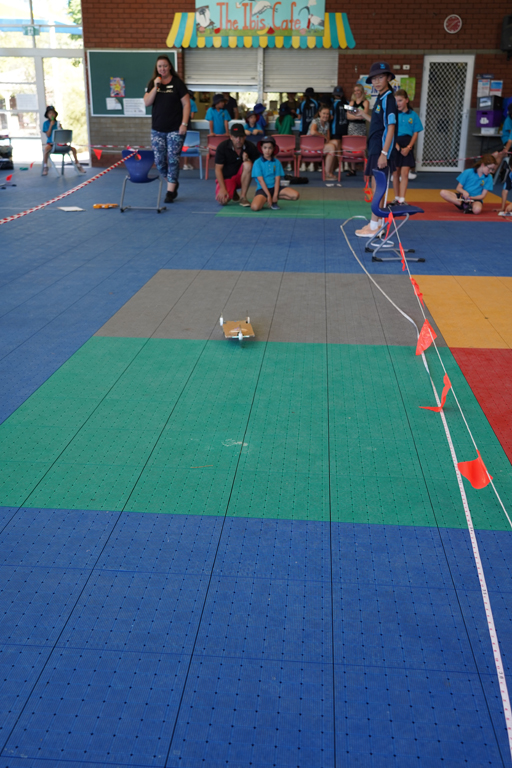

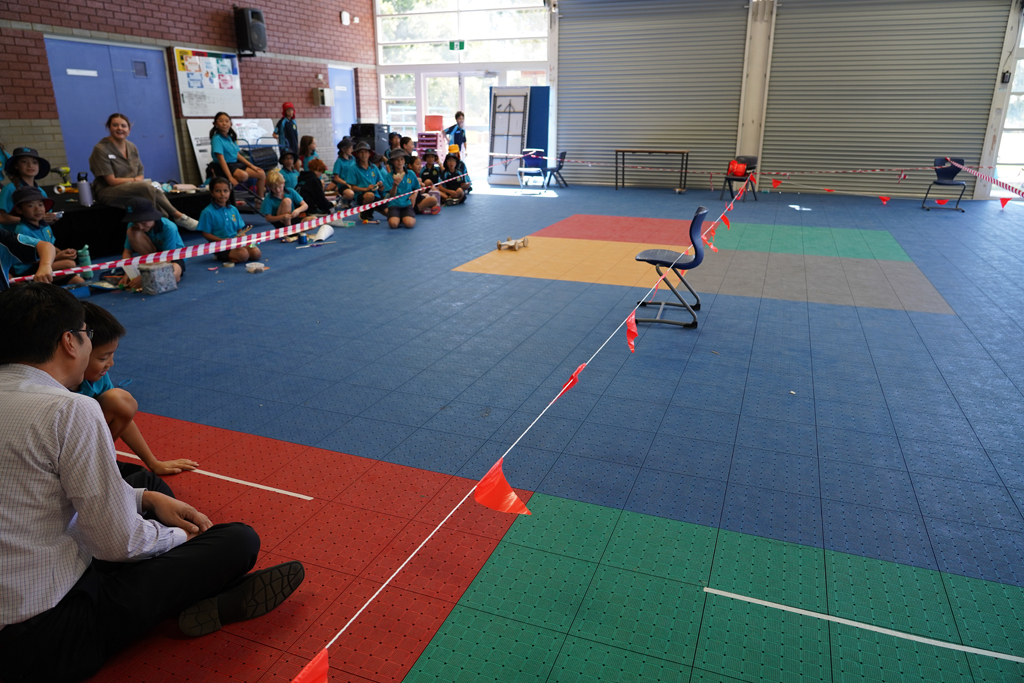

While most of the time may have been spent in ‘pit lane’, congratulations to the teams who managed to get their vehicles on the road and recorded a score. We will go away and determine the score for each team, based on the distance their car travelled and what materials were used. The winners will be announced at an assembly early in term 2.

We would also like to acknowledge the fantastic work put in by our family entries. Congratulations to the Lim, Belotti, Ariyaratnam and Corke families for their amazing Rubber band cars and good sportsmanship on competition days. It is always fantastic to see parents and children working together, and we could tell by the pride on everyone’s faces that there was a lot of love put into their creations. Well done – some amazing results too!

A huge thank you needs to go to Mrs Jenkin for her tireless energy and enthusiasm in organising this fantastic event for our students. Well done Mrs Jenkin – absolutely brilliant! Also, another huge thank you to the STEAM team for their amazing work in the lead-up and running of the event.

Check out all the action in the gallery below.

Our 2024 STEAM Calendar kicks off with the annual Engineering challenge, and this year it is a beauty! The STEAM team will be facilitating students and families to get their creative and problem-solving abilities in full swing as part of the RUBBER BAND CAR challenge.

This year we will be running two versions of the challenge simultaneously.

Throughout lunchtimes of week 9, students across the school will have the opportunity to participate as part of a team, designing, building, and testing their vehicle, and ultimately competing for some great prizes!

This year, we would love siblings and families to also participate from home. Following the guidelines and information provided below, families are encouraged to source the allowed materials and get building and testing! Coinciding with the week 9, in-school competitions, we will run our Community Cup division – where family entries will be run and raced against each other in search of the best CPS Rubber Band Car!

All CPS winning entries will be entered into the global 2024 Science Buddies competition, as our representatives for our chance to win up to $10,000.

Please note that a ‘Rubber Band Car Score Sheet’ (attached below) must be printed off and accompany any model participating in the Community Cup.

Register your family here for this great event

Good luck and good engineering everyone!

CALL for recyclable materials! – If you have any plastic lids or old cd’s that you don’t need anymore – please consider donating to the school to help stock our smorgasbord of materials for the students to use in the challenge. Please drop off any materials to the office, before week 9.

Cheers!

Rubber Band Car—2024 Engineering Challenge

Can you build a car powered by nothing but a rubber band? The farther the car goes, and the fewer materials you use to build it, the higher your score. Students across the globe are invited to try the 2024 Engineering Challenge We are excited to see what you build!

Introduction

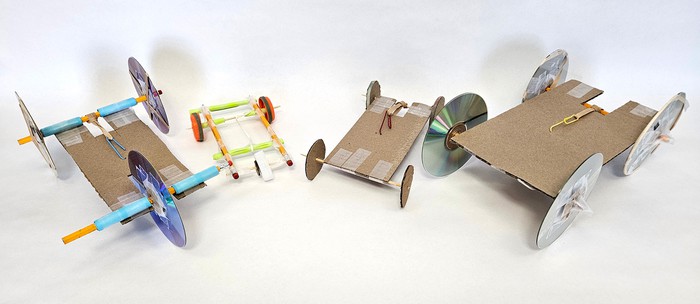

Rubber band-powered cars, like the ones in Figure 1, can be made from a variety of materials, but they all have one thing in common. A rubber band is wound around an axle, a cylindrical rod that passes through the centers of the wheels. As you twist the axle and tighten the rubber band, it stretches and stores elastic potential energy. When you release the axle, the rubber band contracts, and this potential energy is converted to kinetic energy, the energy of motion, and the wheels will spin. Depending on the amount of friction with the ground, the wheels might propel the car forward, or they might just spin in place! The frictional force between the wheels and the ground depends on both the weight of the car and the coefficient of friction, which depends on the materials the wheels and ground are made of. That is a lot of physics in one little device!

Materials

To enter your students’ designs in the 2024 Science Buddies Engineering Challenge, you can only use the following materials.

| Material | Size/type restrictions | Maximum quantity | Points (each) |

|---|---|---|---|

| CDs or DVDs | n/a | 4 | 2 |

| Plastic bottle caps | Any size. No metal lids. | 4 | 2 |

| Paper | Printer, construction, graph, or notebook paper (letter, A4 size, 9″x12″, or 22×30 cm sizes are all allowed) | 10 sheets | 1 |

| Wooden pencils | n/a | 10 | 1 |

| Plastic or plant-based/biodegradable drinking straws | Any size. No metal straws. | 10 | 1 |

| Wooden skewers | n/a | 10 | 1 |

| Paper clips | Maximum length 1-3/4″ or 45 mm | 10 | 1 |

| Sheets of cardboard | Maximum 12×12 inches or 30×30 cm | 2 | 10 |

| Rubber bands | Maximum size #64 (3-1/2×1/4 inches or 90×6 mm when laid flat and unstretched) | 10 | 2 |

| Tape | Maximum 1 inch (2.5 cm) wide. Clear office tape, masking tape, or painter’s tape.

Duct tape, packing tape, and electrical tape are not allowed. |

1 roll | 5 |

Rules

- You must build a vehicle with a frame, at least one axle, and at least one wheel.

- The car must be a single device. No parts of the car can intentionally or unintentionally detach, fall off, or otherwise separate during the test.

- The car must be powered entirely by one or more rubber bands. No other sources of forward force or movement, such as pushing or blowing on the car, are allowed.

- All rubber bands that power the car must be pulled/twisted/tightened, etc. by hand by up to two people. No additional external tools or sources of leverage that are not part of the car (wrenches, power drills, etc.) are allowed to help tighten the rubber band.

- The test must be conducted on a flat surface. Any surface (carpet, wood, concrete, etc.) is acceptable.

- A straight start line must be marked on the floor, using any material that will not create a bump or impede the car’s motion (tape, chalk, etc.). The car must start completely behind the start line.

- After the car has been released, no one can touch the car, and it cannot touch or bump into any objects, until it comes to a complete stop on its own.

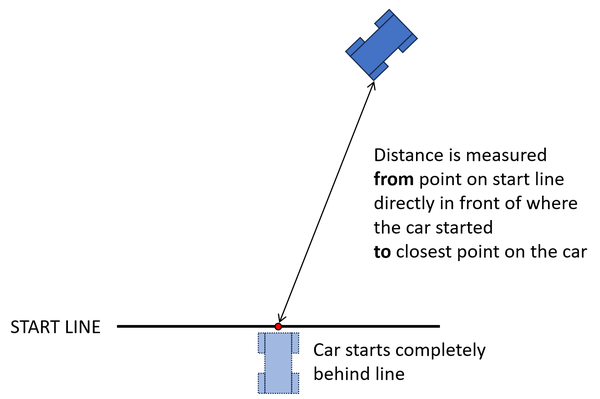

- After the car has come to a complete stop, distance is measured from the point on the start line directly in front of where the car started to the closest point on the car (Figure 2).

Design

Before you start building anything, it is a good idea to brainstorm different designs. If you need help getting started, look at the cars in Figure 1 and closely re-watch the introduction video. Try sketching your designs out on paper (paper used for sketching does not count toward the total used to build your device). Remember that there is a potential trade-off in your design. You might be able to build a better, sturdier car that goes farther using more materials, but each material costs a certain number of points. Your score depends on both how far your car goes and how many materials you use to build it. Can you figure out how to make good use of materials and efficiently build a car that goes as far as possible?

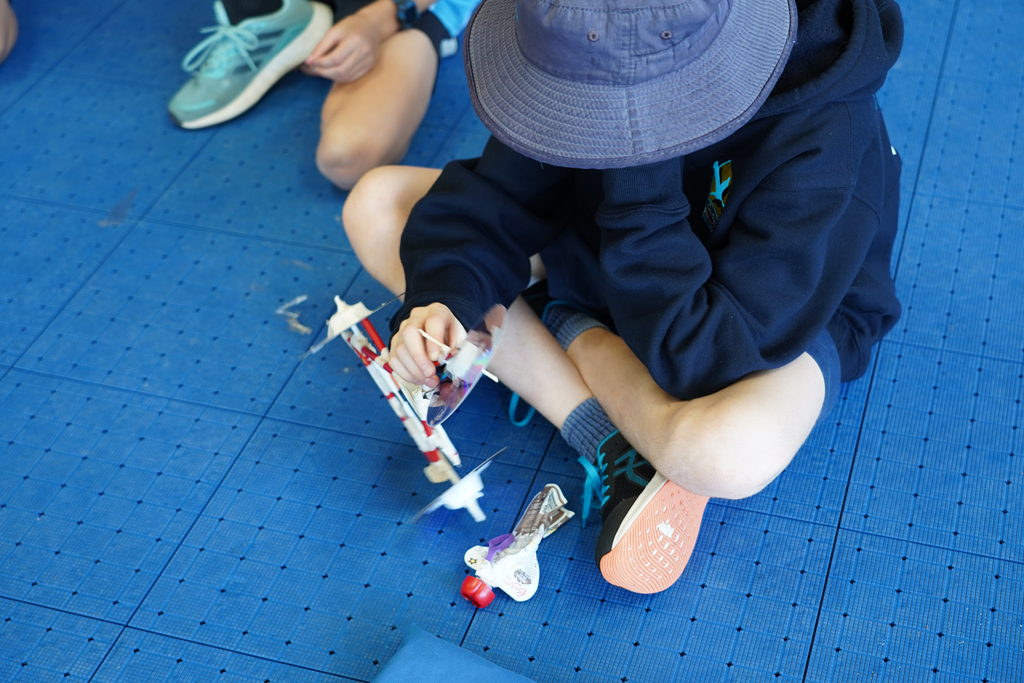

Build

Once you have a design, it is time to start building. You might want to build in stages, testing different parts of your car one at a time. For example, you might want to first make sure the axles spin smoothly when you spin them by hand. Next, you can put your car on the ground and see if it rolls when you push it. Finally, you can wind up the rubber band and see if it will propel the car forward when you let go. You might find that your design does not work out as planned once you start building, and that is OK! You can go back and change parts or even all of your design.

Test

Once you have finished building your car, you should test it on a flat surface free from obstacles. Wind up the rubber band, place your car on the ground, release it, and watch it go. Watch your car carefully. What happens? Do the wheels grip the ground, or do they spin too fast and slip? Do the axles spin smoothly, or does the car’s motion look bumpy? Does it go straight or curve off to one side? Think about ways you can improve your car’s performance and make it go farther. You can also think about ways you can remove materials or start over and build a new car with fewer materials (only materials used in your final design count when calculating your score). Iterate through the design, build, and test process until you are ready for an official test.

Official Test

When you are ready for an official test, make sure you have a start line marked on the floor. Mark a point on the start line using a marker or a piece of tape. Wind up the rubber band (up to two people can do this—it may be easier if one person holds the car while another person twists the axle), place the car on the floor completely behind the start line, centered directly behind the point you marked, and let it go. Watch the car and make sure it does not bump into anything and that no one touches it until it comes to a complete stop on its own. Once the car has stopped, use a tape measure to measure the distance from the point on the start line to the closest point on the car (see Figure 2). Write this distance down. If at any point during the test you break one of the rules, you must start the test over.

Scoring

Your score is calculated using this equation:

Equation 1: